In our dips so far into The Tower Handbook, we have not looked at the last section, on “Maintenance”. Perhaps you consider this a specialist topic, and “someone else’s job”. But if we all thought that, the bells we expect to be there for us to ring would fall into disrepair. As the book points out, much maintenance involves “the sort of jobs that you can carry out with little or no specialist knowledge. Most routine maintenance includes a lot of common sense and what follows is intended as general guidelines to point you in the right direction.”

The chapter starts with a bellhanger’s maxim:

“If it moves it should move freely.

If it doesn’t move it should be fixed firmly”

It has sections on all the major items of equipment; Frame, Headstock, Bearings, Wheel, Stay, Pulley, Clapper, Rope, Bell and Sound control, together with ones on: Safety, Miscellaneous (some things don’t fit anywhere else!) and a table of “Symptoms and what to check”. Ropes are perhaps the most familiar part of a ringing installation to non technical folk, so we will dip into that section. It has answers to 19 questions. Here is a sample.

i. Why do ropes seem to fail very quickly?

Ropes go for a long time with little sign of wear. When they do start to fail two things happen that hasten the rate at which the whole rope breaks up.

When one strand starts to weaken it stretches a little and that leaves more stress on the others.

When the fibres in the rope start to break up that part of the rope becomes looser and more flexible than the rest, so it takes more than its fair share of the bending. This is especially true in the tailend.

l. What is a splice?

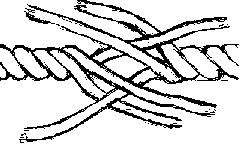

A splice is a way of joining rope without the lumps that would be caused by a knot. All splices involve un-twisting the strands of the rope end and then “weaving” these in between the strands of the piece to which it is being joined:

The first step in making a splice

q. Can you splice synthetic rope into hemp?

Yes. There is a myth that you can’t, but it has been done and works well. Some bell rope manufacturers twist the fibres together before the rope is laid up, giving an almost invisible join (sometimes misleadingly called “machine splicing”). If you buy the new rope to splice onto a good sally and tail end, you do not have this option. The two types of rope have different properties (the synthetic rope is softer and more slippery) so you need a little more than an ordinary short splice. Make it longer than normal (say 5 passes each side), and make the taper much more gradual (say 4 passes each end).

Other questions answered:

- What attention do ropes need?

- How can we reduce rope wear above the sally?

- Why do some ropes have a leather sleeve round the rope?

- How can I prolong rope life below the sally?

- How can I stop the rope end fraying?

- Why do bits of fluff come off the sallies?

- Do sallies ever break?

- Do you need to put lubricant on the ropes?

- Can I repair broken ropes?

- How do I do a splice?

- Are all splices the same?

- Should we use synthetic ropes?

- Can the whole rope be made of synthetic material?

- How do I work out the length of replacement ropes?

- What can we do about damp ropes?

These short articles dipping into The Tower Handbook have given you 22 answers. But there are over 800 in the book, so you will have to read the others for yourself.

Where can I get it?

The Tower Handbook is available from: Central Council Publications